Products Introduction

Welcome to our product page for Polyfoam Moulding, a versatile and durable material used for a variety of applications.

Polyfoam Moulding is a lightweight and cost-effective alternative to traditional wood moulding, which is often heavy, prone to warping, and requires frequent maintenance. Our Polyfoam Moulding is made from high-density expanded polystyrene (EPS) foam, which is molded into various shapes and sizes to suit your specific needs.

One of the key benefits of Polyfoam Moulding is its versatility. Our product can be used in both interior and exterior applications, including decorative trim, crown moulding, window and door surrounds, and architectural details. It can also be easily customized to fit any design or style preference, making it a popular choice for both residential and commercial projects.

Another advantage of Polyfoam Moulding is its durability. Unlike traditional wood moulding, our product is resistant to moisture, insects, and decay, ensuring a longer lifespan and less frequent maintenance. It is also lightweight, making it easy to handle and install, which can save both time and labor costs.

In addition to its practical benefits, Polyfoam Moulding also adds aesthetic value to any project. Our product is available in a variety of textures and finishes, including smooth, rough-hewn, and wood grain, which can be painted or stained to match any color scheme. It can also be used to create intricate designs and patterns, adding a touch of elegance and sophistication to any space.

At our company, we are committed to providing high-quality Polyfoam Moulding that meets the needs of our customers. Our product is manufactured using state-of-the-art technology and undergoes rigorous testing to ensure its durability and longevity. We also offer a wide range of customization options to ensure that our product meets your exact specifications.

if you are looking for a lightweight, durable, and versatile material for your next project, consider Polyfoam Moulding. With its numerous benefits and customization options, it is a practical and stylish choice for any application. Contact us today to learn more about our product and how it can enhance your next project.

Product Application

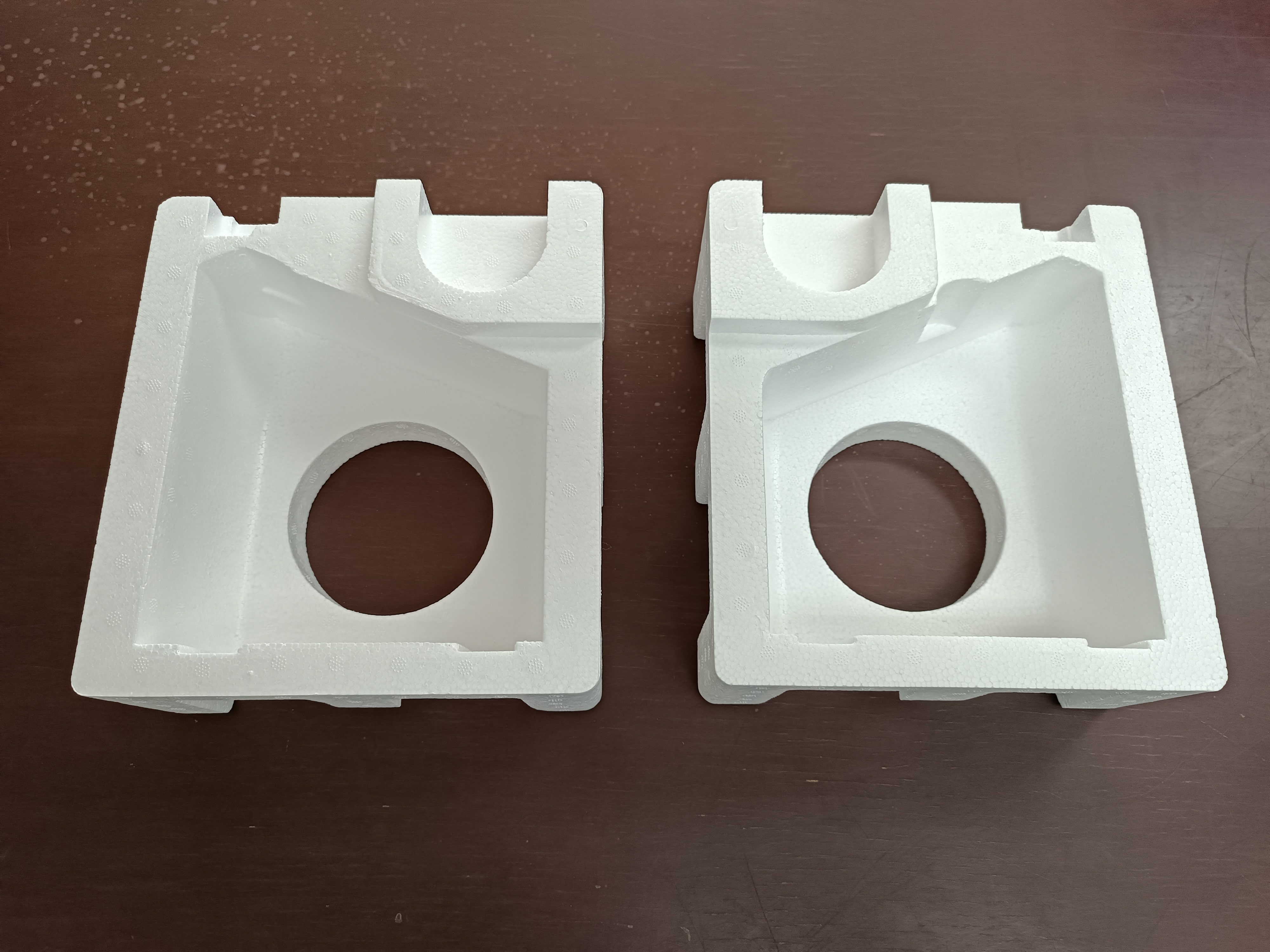

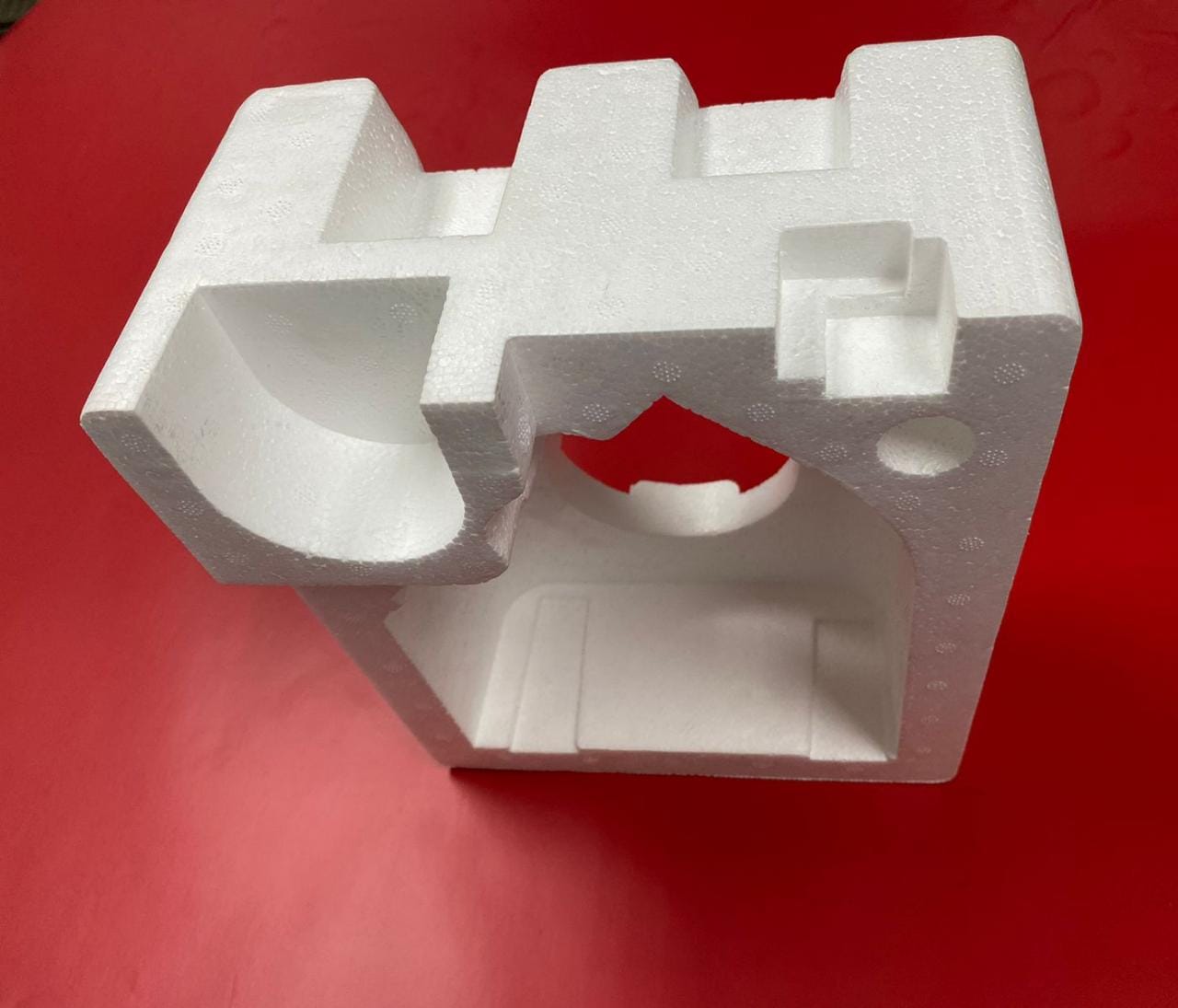

EPS Polyfoam Moulding is also commonly used in the packaging industry due to its lightweight, shock-absorbing properties. Here are some of the most common applications:

- Protective Packaging: Polyfoam Moulding is an excellent choice for protective packaging of delicate and fragile items such as electronics, medical devices, and glassware. It can be easily molded to fit the shape of the item, providing a secure fit and protection during shipping.

- Insulated Packaging: Polyfoam Moulding is a good insulating material and is often used to protect temperature-sensitive products such as food, pharmaceuticals, and chemicals during transportation. It provides a barrier against temperature fluctuations and helps maintain the product's integrity.

- Void Filling: Polyfoam Moulding can be used as a void-filling material to prevent products from shifting during transportation. It can be easily cut and shaped to fill any empty spaces in the package, providing extra cushioning and protection.

- Corner and Edge Protection: Polyfoam Moulding can be used to protect the corners and edges of a product during shipping. It can be easily cut and shaped to fit the product's specific dimensions, providing extra support and cushioning.

- Dunnage: Polyfoam Moulding can be used as dunnage, which is the material used to fill the space between products in a container to prevent them from shifting during transportation. It provides cushioning and protection, reducing the risk of damage to the products.

Polyfoam Moulding is a versatile material that is commonly used in the packaging industry due to its lightweight and shock-absorbing properties. Its customizable features and ease of use make it a practical and cost-effective choice for packaging applications.

Product Material

EPS (Expanded Polystyrene) is the primary material used for Polyfoam Moulding packaging. EPS is a lightweight, rigid, and closed-cell foam made from polystyrene beads that are expanded with steam and molded into various shapes and sizes.

EPS has excellent shock-absorbing properties, making it an ideal material for protective packaging. It can withstand multiple impacts without losing its cushioning properties, providing a high level of protection for delicate and fragile products during shipping and handling.

EPS is also an excellent insulator, making it a popular choice for packaging perishable goods that require temperature control during transportation. EPS can maintain the temperature of the contents inside the package, keeping them cool or warm as needed.

In addition to its cushioning and insulating properties, EPS is also moisture-resistant, making it an excellent choice for products that may be exposed to moisture during transportation or storage. EPS is also resistant to most chemicals and can withstand exposure to solvents, acids, and alkalis.

EPS is a versatile and reliable material for Polyfoam Moulding packaging due to its lightweight, shock-absorbing, insulating, and moisture-resistant properties.